Technology

Encapsulation technology essentially deals with the incorporation of commercially available

active material into protective system that can deliver the active to specific site.

Encapsulation technology essentially deals with the incorporation of commercially available

active material into protective system that can deliver the active to specific site.

Skin, hair and mucosal surfaces are useful targets for the delivery of active compounds.

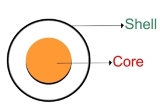

The core is covered by solid shell which is used to deliver, protect stabilize or control the release of the core/active

Protective Shell

Usually selected from a list of materials “generally regarded as safe” (GRAS) to meet the

Usually selected from a list of materials “generally regarded as safe” (GRAS) to meet the

needs of the application as well as regulatory demands e.g.. Biodegradability- USP Grade

- Suitable for personal care use

Core

Ingredients

Ingredients - encapsulated include

- colors, fragrances, flavors, vitamins & oils etc.

Target Delivery

Skin, hair and mucosal surfaces are useful targets for the delivery of active compounds.

Skin, hair and mucosal surfaces are useful targets for the delivery of active compounds.

Level of Incorporated active

Will depend upon the nature of the active ingredients being encapsulated.

Will depend upon the nature of the active ingredients being encapsulated.

Reasons to employ an encapsulation:

Superior handling of active material (e.g. conversion of liquid active agent into a powder).

Superior handling of active material (e.g. conversion of liquid active agent into a powder).- Improved stability in fnal products during processing (e.g. less evaporation of volatile active).

- Creation of visible effects.

- Adjustable properties of active components (particle size, structure, oil or water soluble color.

- Off taste masking.

- Controlled release.

Types of Encapsulated Beads

Pressure release / burst release / water penetration control system.

Pressure release / burst release / water penetration control system.- This is design as water as the main agent controlling the release of the active.

- In this system active molecules cannot physically diffuse out the device without water molecule diffusing in

- This is usually achieved by incorporating actives in hydrophilic polymer that is stiff when dry but swells when placed in aqueous environment.

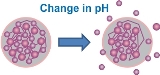

pH Responsive Beads.

- In this technique beads are coated with ionic pH sensitive polymers having as

main feature that they release protons

in response to pH change. - Having a structure acid or basic groups that can accept or release protons in response to pH change in surrounding

environment.

Color in color Beads.

- These beads gives color changing effect on rubbing.

- Color in color beads is a simple concept where in the core is of one color and the out shell can be of different color.

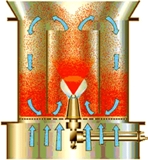

- The process consists essentially of spraying a color solution fluid on to particles of substrate material undergoing encapsulation.

- This is achieved by fluid bed coating.

Oil encapsulation

- The encapsulation method provided beads where oil droplets were well dispersed and protected.

- The wall material used commonly includes synthetic polymer and natural biomaterials (usually carbohydrates).

Flavor and Fragrance Encapsulation

- Encapsulation of flavor and fragrance in dedicated shell.

- It can limit the degradation or loss of the flavor during the various product process and storage.

- The shell can also provide the functional properties such as control release of aromatic molecules in given environment.

Film Casting

Films are hydrophilic and temperature sensitive in nature.

Films are hydrophilic and temperature sensitive in nature.- It dissolve upon contact with wet surface such as tongue within few seconds.

- We can encapsulate oil and color in various attractive shapes.

Black Cellulose Beads

Black Cellulose Beads

Blue Cellulose Beads

Blue Cellulose Beads

Golden Cellulose Beads

Golden Cellulose Beads

Green Cellulose Beads

Green Cellulose Beads

Multicolor Cellulose Beads

Multicolor Cellulose Beads

Orange Cellulose Beads

Orange Cellulose Beads

Yellow Cellulose Beads

Yellow Cellulose Beads

Red Cellulose Beads

Red Cellulose Beads

Violet Cellulose Beads

Violet Cellulose Beads

PearlyBlack Color Beads

PearlyBlack Color Beads

PearlyGolden Color Beads

PearlyGolden Color Beads

PearlyGreen Color Beads

PearlyGreen Color Beads

Green Color Surprise Beads

Green Color Surprise Beads

Pink Color Surprise Beads

Pink Color Surprise Beads

White Color Surprise Beads

White Color Surprise Beads